TECHNIQUE

Learn more about our construction techniques and discover the characteristics of our Airgym Pro and Basic series. Both are made with the best materials and are 100% safe. There are huge differences when you compare inflatable products from other brands in terms of quality, performance, durability and safety to ours. At Airgym we use the most revolutionary weaving structure that is different from any other brand. It assures you the best user experience.

All our

Used Components

Double wall fabric

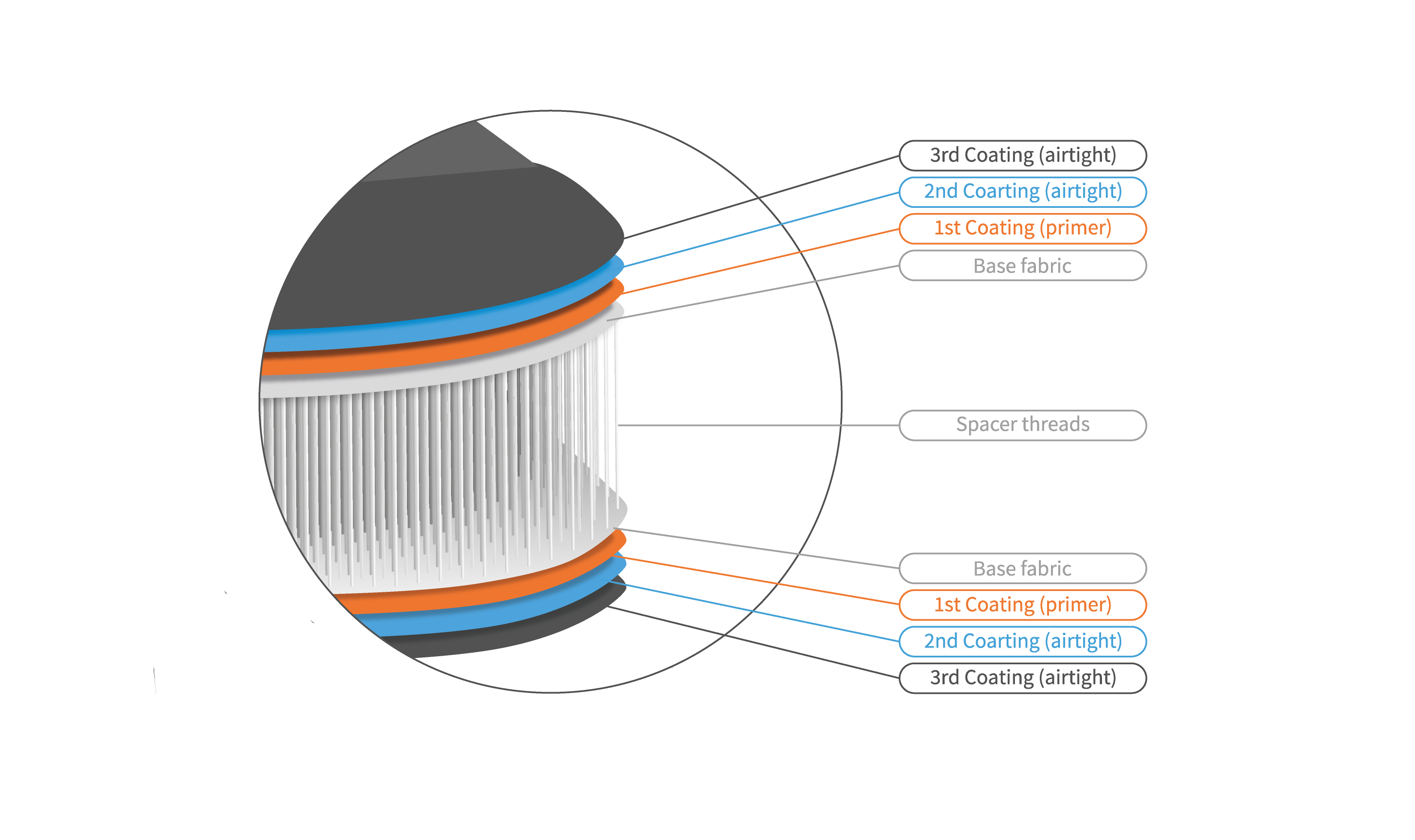

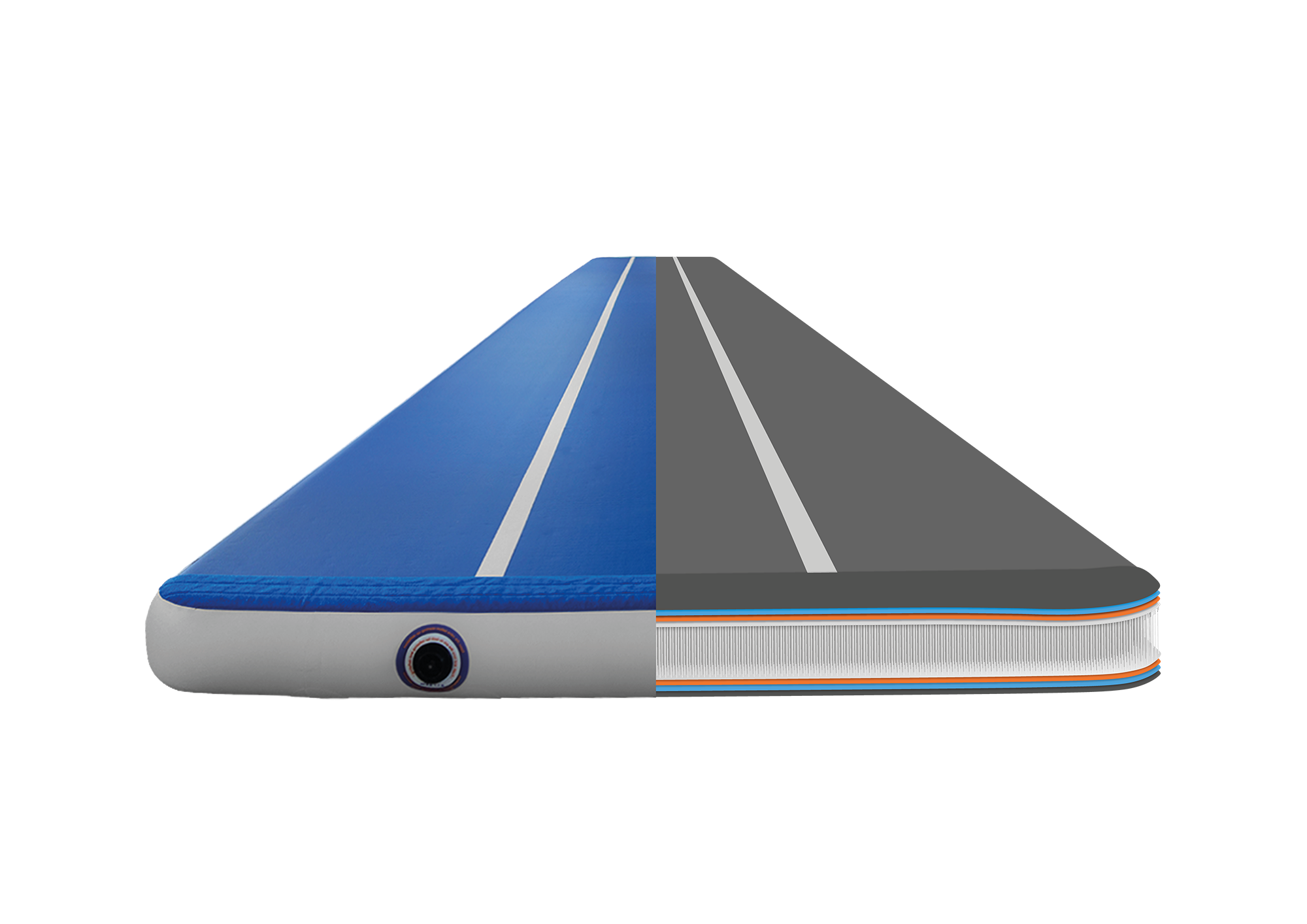

Heart of the Airgym air products is the Double Wall Fabric (‘DWF’). ‘Double Wall’ is a three- dimensionally structure whose two base fabrics are interlinked with tenths of thousands of spacer threads, which specify the thickness and parallelism of the material. The fabric is covered on both sides with several layers of coating. This combination makes the air products evenly flat, airtight and lightweight.

The emerging hollow body between the base fabrics can be filled with different media like air, water or sand. The filling, however, guarantees the obtainment and keeping of the desired shape of the hollow body – a dimensionally stable surface. Depending on air pressure or filling quantity a bending resistant unit or a mattress with a continuously variable degree of hardness is produced. In case of Airtracks you will receive either an extremely stable or very bouncy surface that can be adjusted in pressure to your likings.

At Airgym we use 2 different types of Double Wall Fabric.

A high-tech woven DWF for the Airgym Pro series and like most other brands a knitted fabric for Airgym Basic. The main difference between the fabrics is the construction technique. Knitting uses single linear polyester threads and creates a straight connection between the top and bottom layers. Weaving consists of multiple threads packed tightly creating a very high-strength and form-locked cross- woven combination of fabric surfaces.

- Biggest advantage from woven is the longevity aspect, when damaged it’s easier to repair over and over again than a knitted fabric.

- Weaving has the strongest and most dimensionally-stable connection.

- The extreme stiffness creates a stable surface with tremendous rebound power and good stress distribution.

Our special woven DWF also has ultra-strong spacer threads and unique coating layers making Airtrack Pro the most supple, softest, bounciest, strongest, torsion stiffest, lightest, best foldable and most durable Airtrack available.

These unique characteristics make Airgym Pro in terms of user experience unbeatable. Professional tumblers and experienced athletes prefer the Pro series because it is simply the best.

That said, there is no wrong series to choose from. Both are high quality products made by the same craftsmen in our factory. It’s a matter of weighing the differences in terms of price, durability and intended use. Want to experience and feel the differences? You can always contact us or your local distributor for more info.

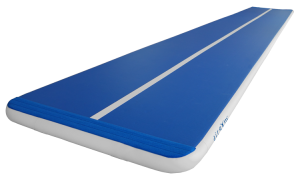

PRO

BASIC

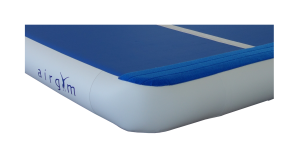

Side walls

As with the Double Wall Fabric our other used PVC fabrics meet the highest quality standards. Like a large number of our used components, the PVC fabric side walls are extremely durable and hard-wearing that find their origins in the boat building industry. The side walls are attached to the DWF with a high-tech gluing process and our special construction techniques.

To allow Airgym air products to operate under a permanently constant amount of air we made high demands on the air valves. Depending on height and length, each product is equipped with one or more valves. The grey non-return valve is used for filling smaller products. The black non-return valve has a bigger air opening and is used for filling and emptying.

Non-return air valves

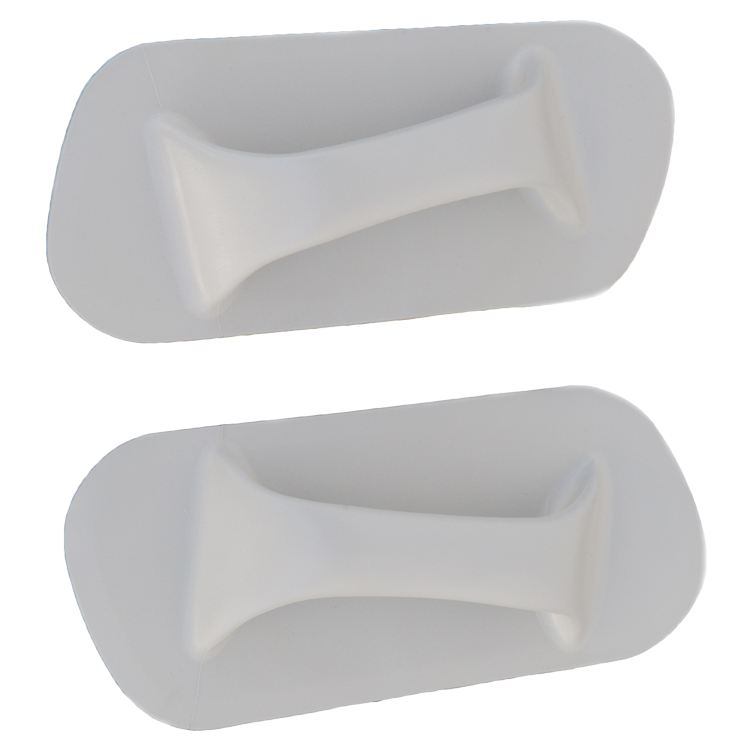

Carrying handles

Each Airgym Pro air product with a minimal height of 15cm is equipped with sturdy PE ‘hard handles’ to ensure maximum flexibility during the training. These handles, also originating from the boat building industry, allow the products to be repositioned any time in their inflated state. Soft handles are used for 10cm high air products and Airgym Basic but exceptional desires to switch hard handles into ‘soft handles’ are possible of course.

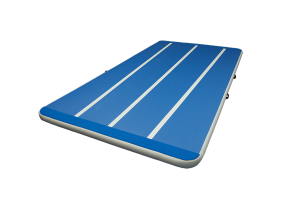

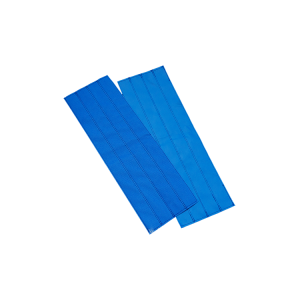

Most Airgym products receive an orientation marking line. Normally the line is used to cover the longitudinal middle seam of the double wall fabric (DWF). Our used lines provide a symmetrical Airtrack and as an extra advantage divides the jumping surface more ‘user lanes’.

Line markings

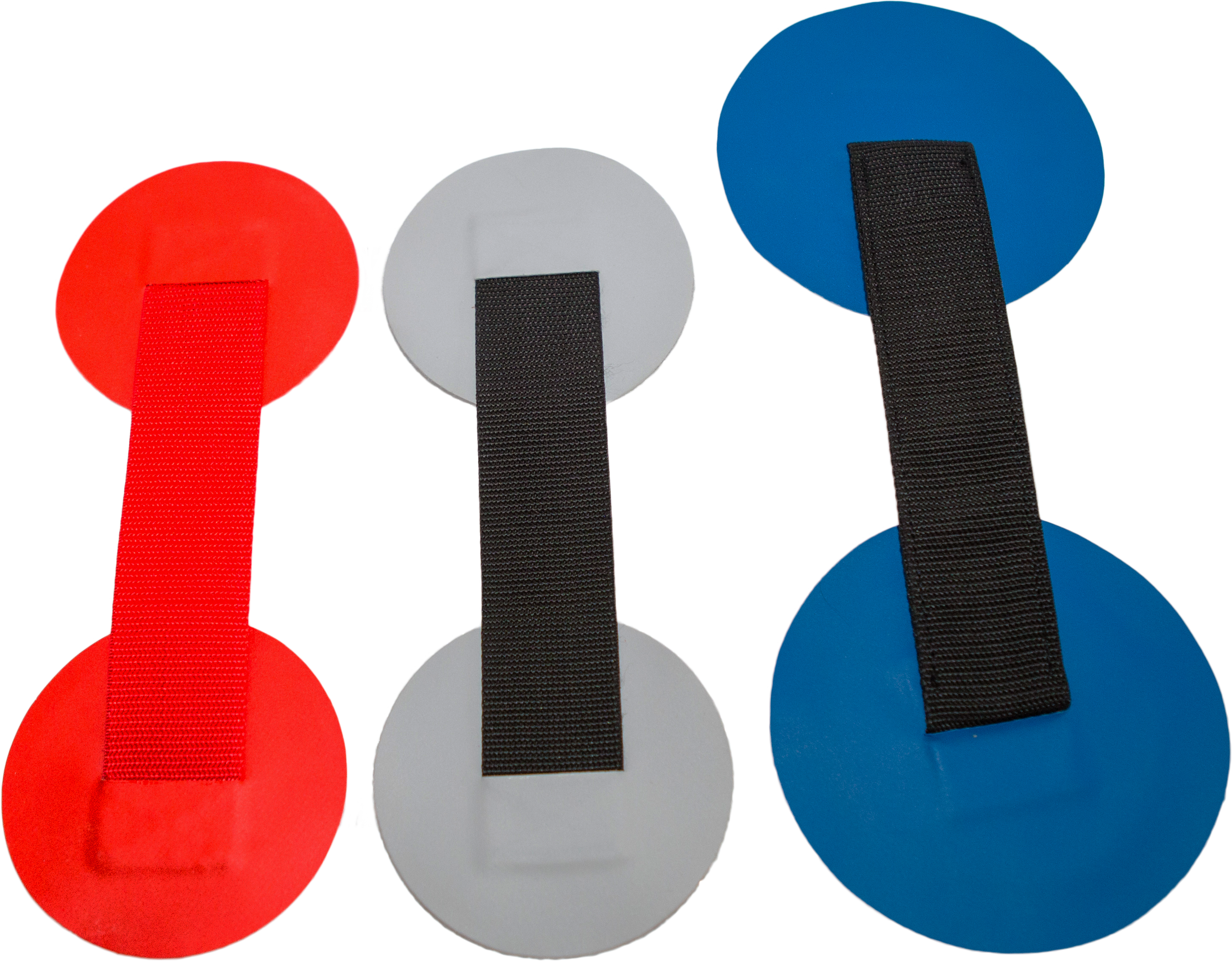

Velcro strips

Also as standard, most Airgym products are equipped with velcro connection strips. They allow a firm connection of run-ups, landing mats or other Airtracks without any problems. Of course, on request more contact areas can be equipped with velcro strips.

WANT TO KNOW MORE ?

Want to experience the differences or need more information? please contact us or your local distributor.